BoardScanner

Superior recovery from high density scanning at the sawmill trimmer.

Raptor's BoardScanner produces the highest value trimmed board presented to the sawmill trimmer. High-density scanning models surface characteristics to accurately identify wane, machine damage, holes, rot along with other surface irregularities. The BoardScanner runs stand-alone or fully integrated with Raptor’s WEBSort, eliminating redundancies and incompatibilities experienced with a separate sorting system.Features

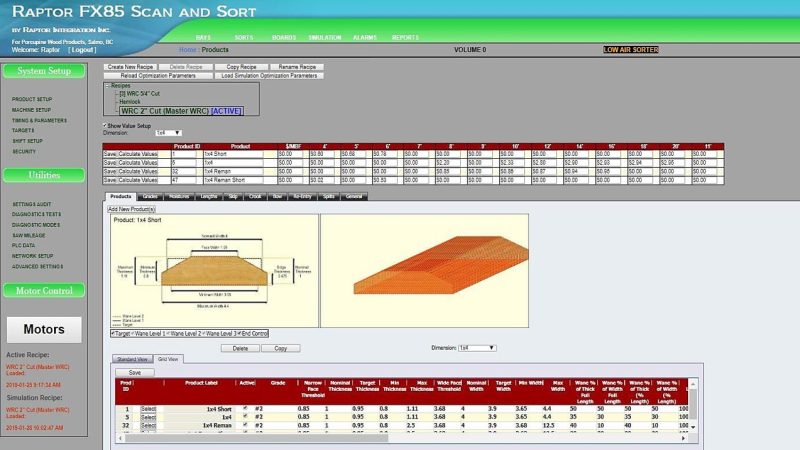

- Customizable grading algorithms to suit product rules defined by the customer

- Board set-up that matches Raptor’s FX85-E edger optimization

- Minimizes resident boards circulating from the edger

- Supports multi-saw trimmers, flying or separate PET

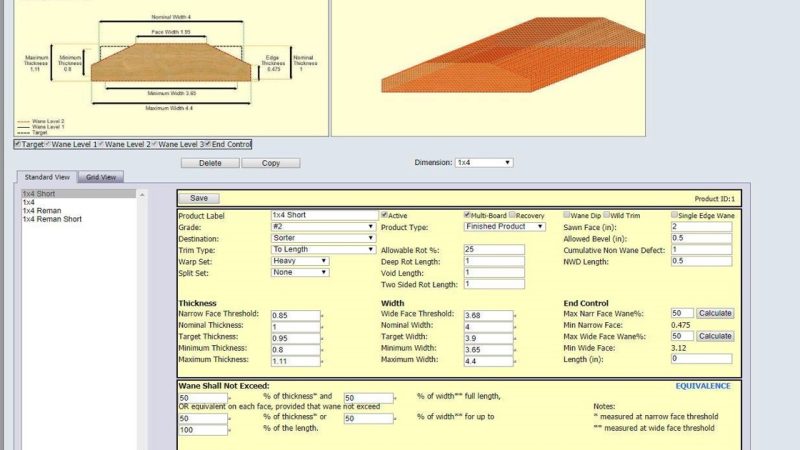

- Can evaluate for single edge and/or single face wane

- Configurable wild trim – lift far or near saw to leave a specified amount of extra wood

- Non-wane defect allowance – deducts certain defects from wane calculations

- Support for multiple wane dips – location and size defined by the user

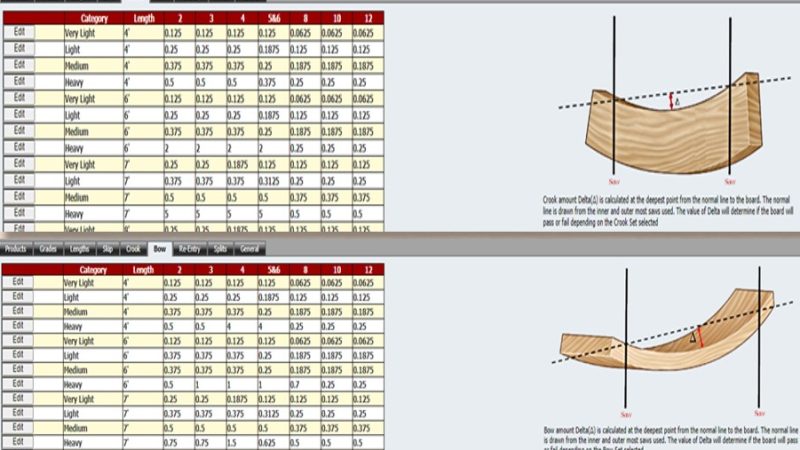

- Logic to detect and trim rot, voids, and splits with three levels of depth configuration

- Unlimited number of grades

- Cosmetic trim controlled by the user

- Extensive multi-board ability including sorting all pieces, dropping out the lower grade, lift saws and sending full length to sorter as well as the configuration of allowed combinations

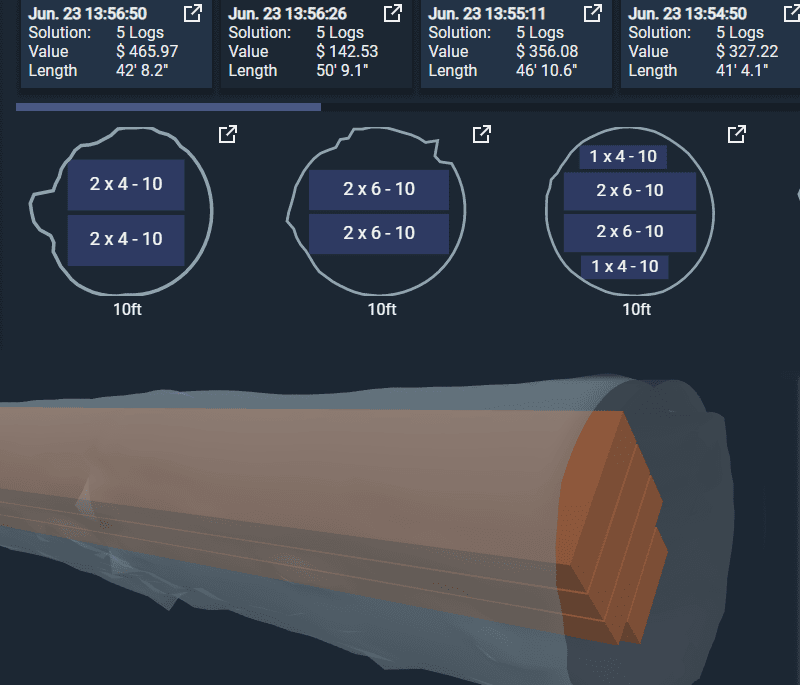

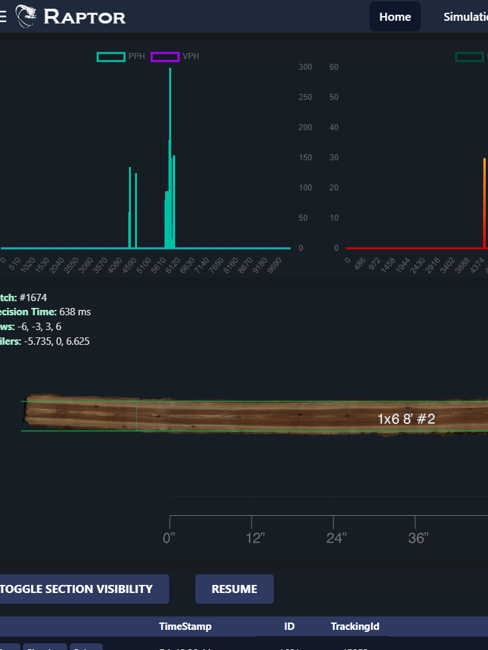

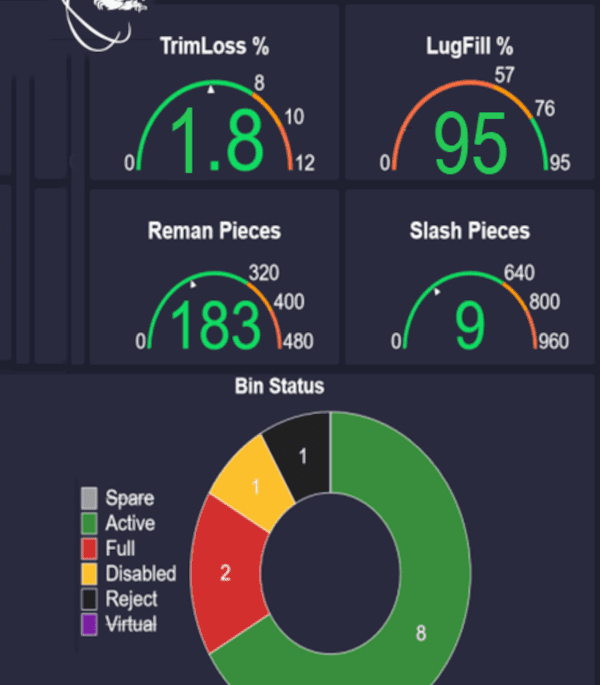

- Intuitive results screen with 3D graphics and critical solution information

- Quick access to solution diagnostics with graphical tools for analysis

- Browser-based user interface. Accessible by tablet or any connected device

- Simulation mode allows users to manually change configuration variables to simulate results and provide in-depth analysis

- Comprehensive reporting package

Specifications

| Sensors (transverse scan) | Laser dot (visible) sensors at .333” @3 kHz |

| Operating System | Windows 10 |

| Data Storage | SQL Server |

| PLC Interface | ControlLogix |