FlitchScanner-Q

Transverse grade scanning for the edger machine center.

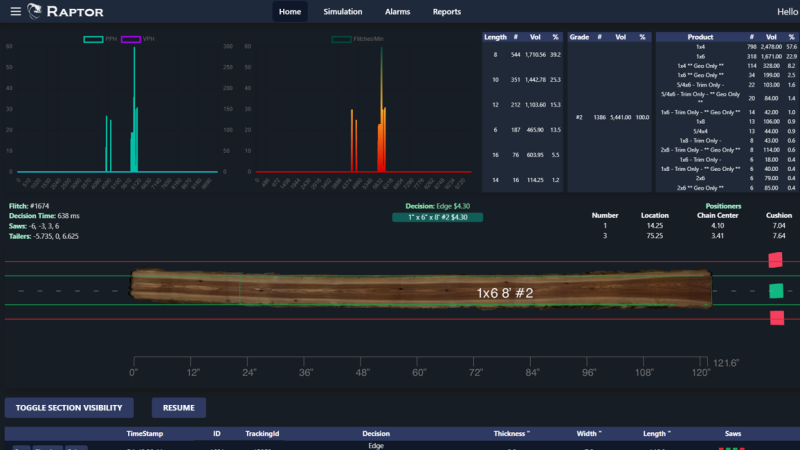

The FlitchScanner-Q (FSQ) is the evolution of Raptor’s vision-based board scanning and optimization, moved upstream to tackle the requirements of the edger. Utilizing the added technologies of colour vision and tracheid analysis the FSQ produces the highest-grade untrimmed boards from the flitch. Proprietary AI software is used to recognize down gradable defects that are incorporated into the solution logic. The FSQ can accurately detect surface defects such as knots, rot, bark, pith, shake, stain, and pitch pockets. This product adds unrivalled control, decision diagnostics and product flexibility to your sawmill.Features

- Board set-up that matches Raptor’s BoardScanner-Q trimmer optimization

- Run full trim logic in each saw gap

- Configurations are available for transverse only

- Supports multiple saw clusters, variable pocket sizes and top chip head

- Balances the use of saws and tailers for even wear

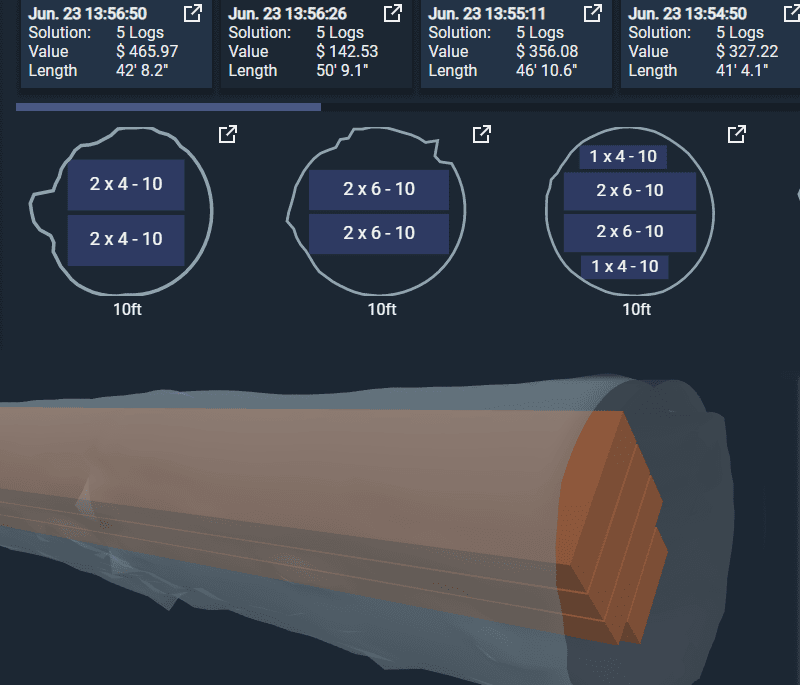

- Intuitive results screen with 3D graphics and critical solution information

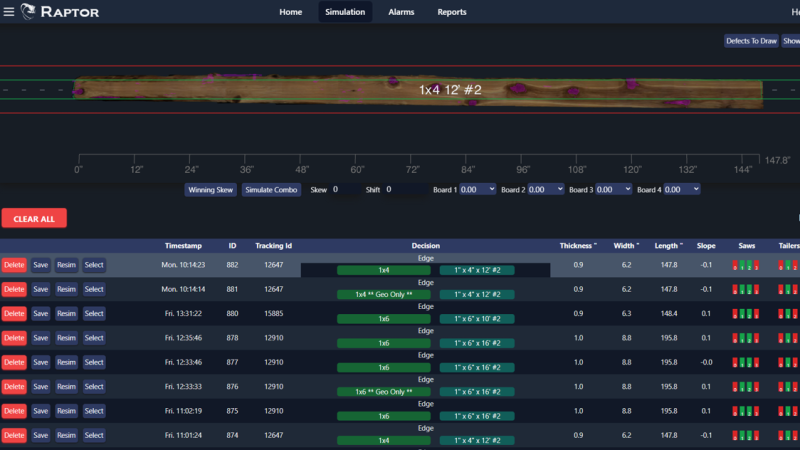

- Easily categorize defects with a click of the mouse

- AI and machine learning improve defect-recognition accuracy as sample size increases

- Quick access to solution diagnostics with graphical tools for analysis

- Browser-based user interface. Accessible by tablet or any connected device

- Simulation mode allows users to manually change configuration variables to simulate results and provide in-depth analysis

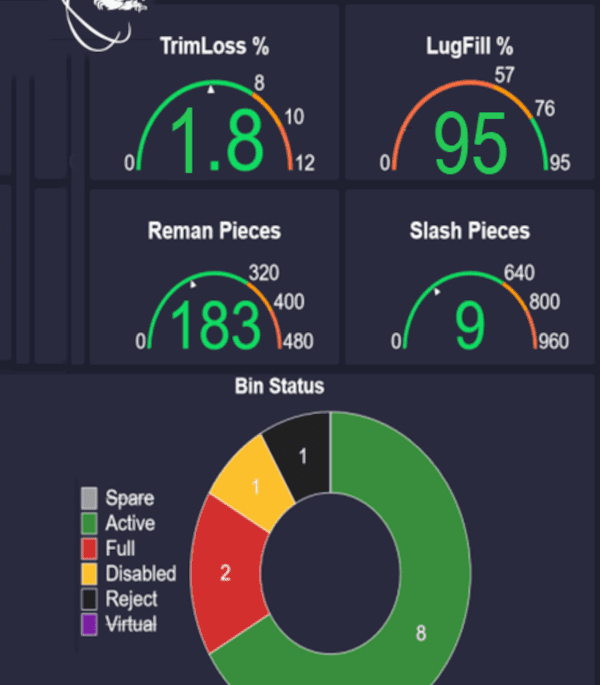

- Comprehensive reporting package

Specifications

| Profile Sensors | Laser dot (visible) sensors at .333” spacing @ 3 kHz |

| Tracheid Speed | 1.5 kHz |

| Colour Vision | 0.02″ x 0.01″ / 0.5 mm x 0.25 mm |

| Sensor configurations | Transverse scanning with single or multi zones. |

| Operating System | Windows 10 |

| Data Storage | SQL Server |

| PLC Interface | ControlLogix |