FlitchScanner

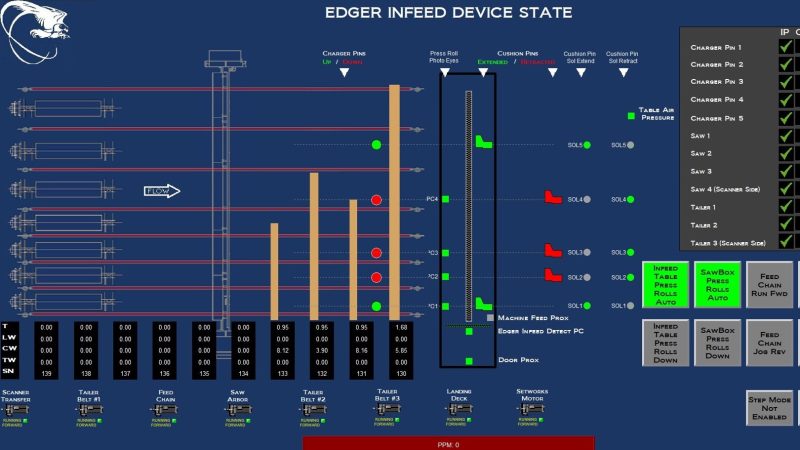

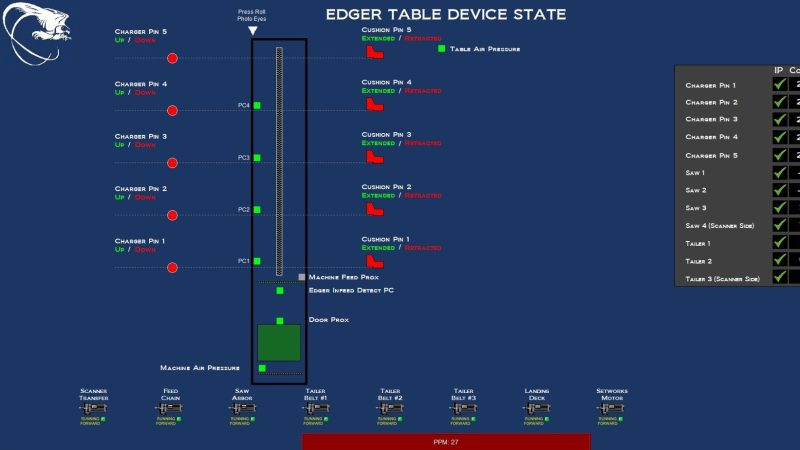

Transverse and lineal scanning, optimization, and controls for the edger.

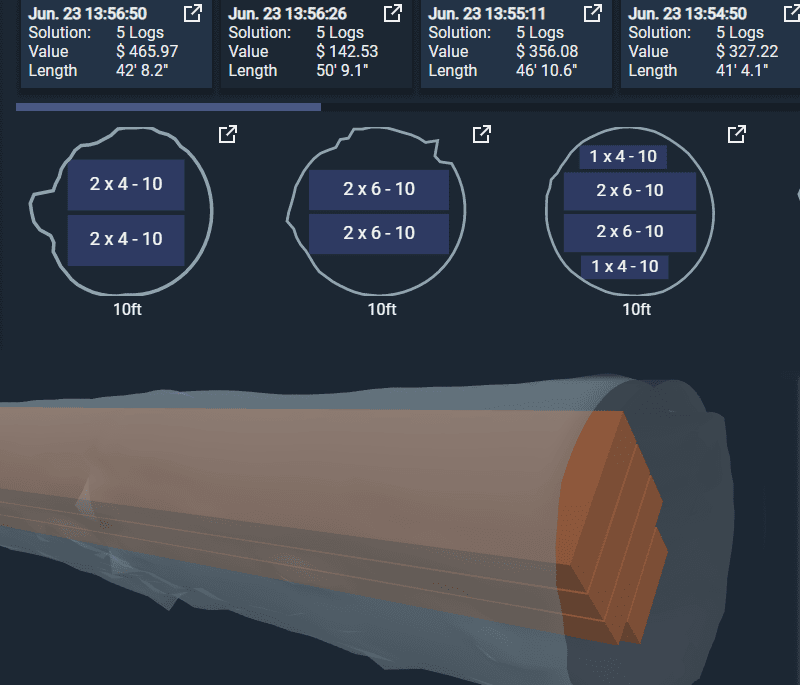

The FlitchScanner produces the highest value untrimmed boards from a flitch at the edging machine center. The system supports configurations for both transverse and linear infeed. High-density 3D modelling enables the optimization logic to identify the smallest of geometric defects, even rot. Multiple scan zones are supported on lineal infeeds to minimize the system's mechanical footprint.Features

- Board set-up that matches Raptor’s trimmer optimization

- Run full trim logic in each saw gap

- Configurations available for transverse or lineal feed systems

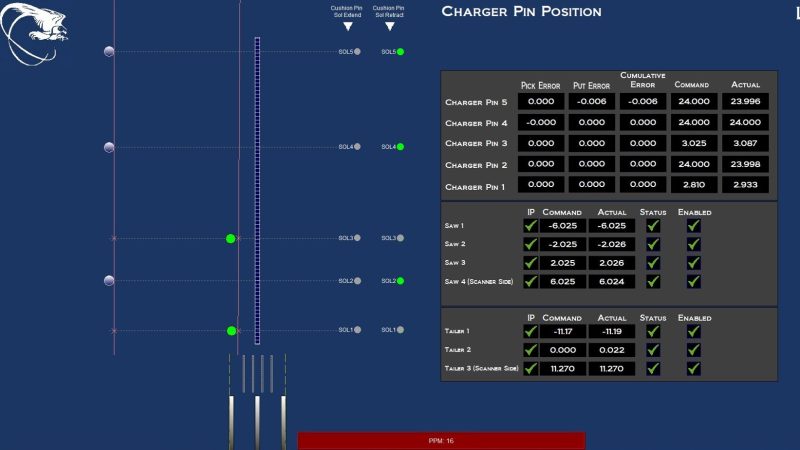

- Supports multiple saw clusters, variable pocket sizes and top chip head

- Balances the use of saws and tailers for even wear

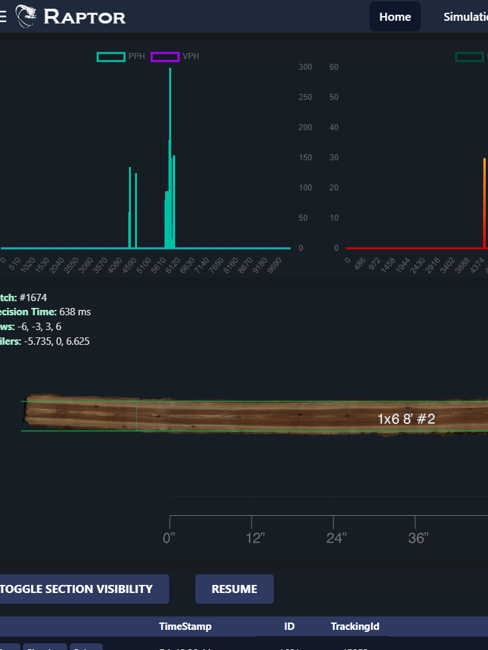

- Intuitive results screen with 3D graphics and critical solution information

- Quick access to solution diagnostics with graphical tools for analysis

- Browser-based user interface. Accessible by tablet or any connected device

- Simulation mode allows user to manually change configuration variables to simulate results and provide in-depth analysis

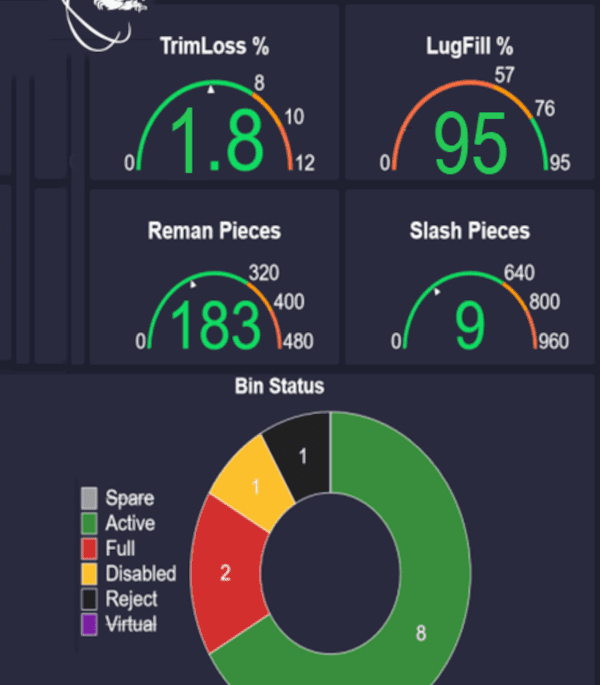

- Comprehensive reporting package

Specifications

| Sensors (transverse scan) | Laser dot (visible) sensors at .333” @3 kHz or 1” spacing @2 kHz |

| Sensors (lineal scan) | Line laser (visible), scanning up to 5,000 Hz |

| Operating System | Windows 10 |

| Data Storage | SQL Server |

| PLC Interface | ControlLogix |